Ceramics have been an integral part of human civilization for thousands of years, with ancient cultures using it to create pottery, decorative objects, and even weapons. However, in recent times, the use of ceramics has expanded into the technical engineering industry. Technical engineering ceramics, also known as advanced ceramics, are specialized materials that exhibit exceptional properties such as high strength, hardness, wear resistance, and thermal stability. We will explore the fascinating world of technical engineering ceramics and their applications in various fields.

What are Technical Engineering Ceramics?

Technical engineering ceramics are a group of ceramic materials that are engineered for specific technical applications. They are usually made from inorganic, non-metallic materials that have been subjected to high-temperature processing and specialized manufacturing techniques. These ceramics have unique properties that make them ideal for use in harsh environments, high-stress applications, and extreme temperatures. Some of the common technical engineering ceramics include alumina, silicon nitride, zirconia, and silicon carbide.

Applications of Technical Engineering Ceramics

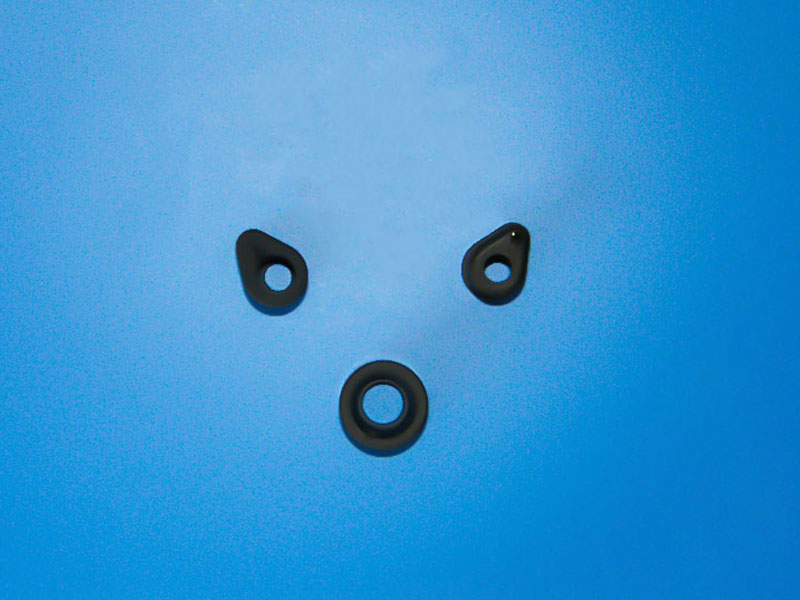

The unique properties of technical engineering ceramics make them useful in a wide range of applications. One of the most common uses of technical ceramics is in the manufacturing of cutting tools, wear-resistant parts, and components for various industries such as automotive, aerospace, and defense. Technical ceramics are also used in the production of medical implants, electronic components, and high-performance bearings.

In the aerospace industry, technical ceramics are used in the production of engine components, including turbine blades, combustion chambers, and heat exchangers. The use of ceramics in these applications allows for the development of lightweight and high-temperature resistant components, resulting in better engine performance and fuel efficiency.

In the medical industry, technical ceramics are used in the production of artificial joints, dental implants, and other prosthetic devices. The biocompatibility and wear resistance of these ceramics make them ideal for use in these applications.

Technical ceramics are also used in the electronic industry for the production of high-performance insulators, substrates, and electronic packaging. The excellent electrical properties of ceramics, such as high dielectric strength, make them ideal for use in electronic applications that require high voltages and frequencies.

Advantages of Technical Engineering Ceramics

One of the main advantages of technical engineering ceramics is their exceptional properties. These materials have high strength, high hardness, and high wear resistance, making them ideal for use in harsh environments and high-stress applications. Additionally, ceramics exhibit excellent thermal stability and can withstand extreme temperatures, making them ideal for use in high-temperature applications.

Another advantage of technical engineering ceramics is their biocompatibility. Some ceramics are compatible with human tissues and can be used in medical applications such as implants and prosthetics.

Moreover, technical engineering ceramics are often more durable and longer-lasting than other materials such as metals and plastics. This makes them a cost-effective option in the long run as they require less maintenance and replacement.

Technical engineering ceramics are a fascinating group of materials with exceptional properties that make them ideal for use in a wide range of applications. From aerospace to medical to electronic industries, ceramics play a crucial role in advancing technology and improving our quality of life. With ongoing research and development, the potential applications of technical ceramics are endless, and we can expect to see even more exciting developments in the future.

EN

EN

Chinese

Chinese