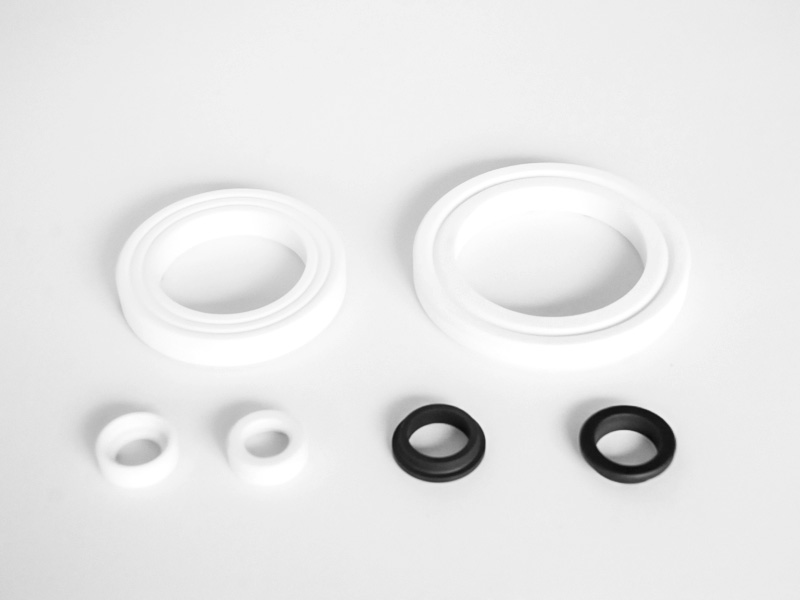

A mechanical seal is a critical component used in pumps and other rotating equipment to prevent fluid leakage. The seal consists of two primary components - the seal ring and the seal face. The seal ring is typically made of a hard, wear-resistant material like ceramic, while the seal face is made of a softer material like carbon or graphite.

Ceramic mechanical seal rings and faces offer several advantages over other types of materials. First, ceramics are extremely hard and wear-resistant, making them ideal for use in high-pressure and high-speed applications. They are also resistant to chemical and thermal degradation, making them suitable for use in harsh environments where other materials may break down.

Ceramic mechanical seal rings and faces also offer excellent dimensional stability, which means they maintain their shape and size even when subjected to extreme temperatures and pressures. This helps to ensure that the seal remains effective over a longer period of time, reducing maintenance costs and downtime.

Another advantage of ceramic mechanical seal rings and faces is their resistance to corrosion and erosion. This makes them ideal for use in applications where the fluid being pumped is abrasive or corrosive, such as in the chemical, petrochemical, and pharmaceutical industries.

Ceramic mechanical seal rings and faces also offer excellent thermal conductivity, which means they can dissipate heat more effectively than other materials. This is important in high-temperature applications, as it helps to prevent the seal from overheating and breaking down.

In addition to their advantages, ceramic mechanical seal rings and faces are also used in a variety of applications. They are commonly used in pumps for the oil and gas industry, as well as in chemical processing equipment and power generation plants. They are also used in food processing equipment, where they offer excellent resistance to corrosion and contamination.

In conclusion, ceramic mechanical seal rings and faces offer several advantages over other materials, including their hardness, wear-resistance, resistance to chemical and thermal degradation, dimensional stability, resistance to corrosion and erosion, and thermal conductivity. These advantages make them ideal for use in a wide range of applications, including those in harsh environments and high-temperature or high-pressure conditions. If you are looking for a reliable and effective mechanical seal solution, consider using ceramic mechanical seal rings and faces.

EN

EN

Chinese

Chinese