Alumina ceramic sheets are very resistant to high temperatures, including 2600deg F (1 022 deg C). The thin sheets can be easily shaped with cutting tools. The thickness of alumina ceramic sheets varies with the percentage of alumina contained in them. They are also available in a variety of lengths and widths. These properties make them ideal for high-temperature industries. Alumina Fine Ceramics are also known for their low cost.

Alumina fine ceramics are hard materials with excellent corrosion, abrasion and heat resistance. They have many applications in the scientific instrument industry, including laser equipment, electron microscopes, microwave windows, and even special crucibles. Their crystalline structure makes them a great choice for complex assemblies. Further, they are excellent thermal insulators and can also be brazed together to provide high-strength connections.

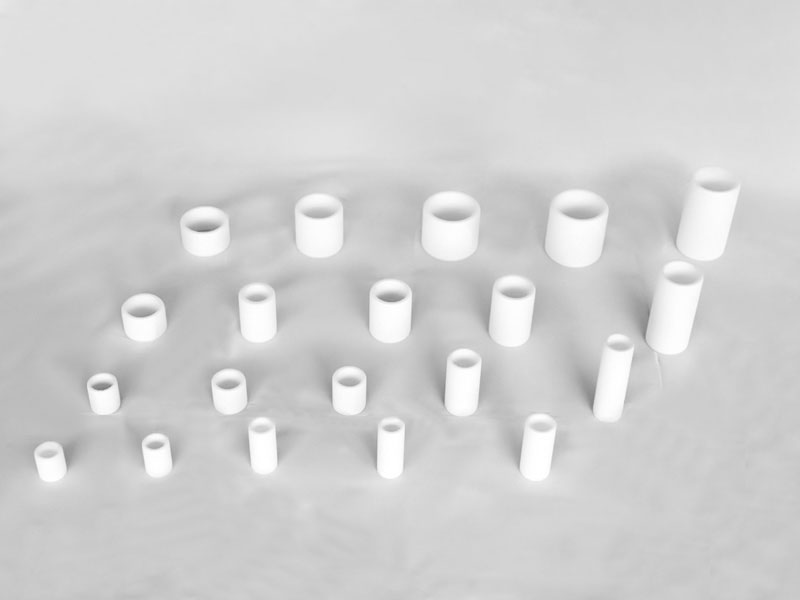

Alumina can be shaped by many techniques, such as compression molding, injection molding, die-pressing, and isostatic pressing. The process is also possible with conventional ceramic techniques. Alumina can be extruded, slip cast and injection-molded, but machining requires diamond tools. These processes are not without their limitations. Nevertheless, many alumina products are not yet suitable for high-temperature environments.

Alumina is the most common fine ceramic. It is a versatile material with a 99.5% to 99.9% Al2O3 content and is usually white or cream in color. Its fine particles are very strong and resist abrasion and other forms of wear. Moreover, alumina is also used to make other materials like glass and metal. The fine particles are the main reason why alumina is so versatile.

Alumina is an extremely pure material, and 99.9% Alumina has excellent thermal and mechanical properties. This material can be used to make plasma etching components, as well as nuclear-grade insulators. It has high strength, and it can be shaped into thin layers that can be fabricated into medical implants and other advanced equipment. This material can also be used in the manufacturing of lasers, X-ray tubes, and microwave windows.

The properties of alumina fine ceramics are varied, but in general, they offer excellent resistance to chemicals and heat. Alumina is among the strongest and hardest ceramic materials known. It is harder than steel and tungsten carbide tools. In fact, alumina ceramics are so hard that they are perfect for mill linings. Their Rockwell hardness rating is 80 to 90. This is above the level of stainless steel and is comparable to diamonds.

EN

EN

Chinese

Chinese